The Impact of Industrial RF Switching Networks: Executing Top Results on the Production Floor

Thermex-Thermatron Systems

Thermex-Thermatron Systems (“Thermex”) has been serving the Industrial Radio Frequency (RF) and Microwave (MW) arenas for over 80 years — creating industry-leading, pioneering technology leveraged on production floors all across the world. Executing a mastery of the physics of RF heating, Thermex provides dielectric heating equipment trusted throughout the sealing and cutting sectors; elevating quality, ramping up efficiency, and ensuring safety.

Transform Dielectric Sealing with the Thermex-Thermatron Automatic Dual Cycle RF Switching Network

It is of the utmost importance that every component of an intelligently designed system be working in optimal condition — especially when the quality of results produced will impact how safe central medical manufacturing solutions become for use. With a system that sequentially supplies RF power to two different points within a sealing die, all during a single press cycle, the Thermatron Automatic Dual Cycle RF Switching Network has been used in RF sealing to serve the medical industry, creating vital IV bags. When an operational RF Switch is in force, any RF-sealed IV bags produced can be used to hydrate patients, keep careful watch on blood pressure, administer medicines to treat infections, and deliver essential vitamins and nutrients.

Each application of RF power is automatically controlled; both for the duration of sealing time as well as for the level of power desired all in an engineered sequence. While this RF Switching System is predominantly used for mandrel sealing (the welding process behind lifesaving medical intravenous bags), other applications have likewise utilized this system, bringing forward new sealing innovations.

Notably, the Thermatron Automatic Dual Cycle RF Switching System comprises two primary components:

Switching Mechanism

Mounted to the upper platen, this mechanism is attached to the RF generator output lead, providing RF power either to the mandrel while grounding the upper platen or the upper platen; all while allowing the mandrel to “float” electronically. Throughout this process, the mandrel is not connected to either the power or the ground. Here, the PLC controls the RF Switch operation.

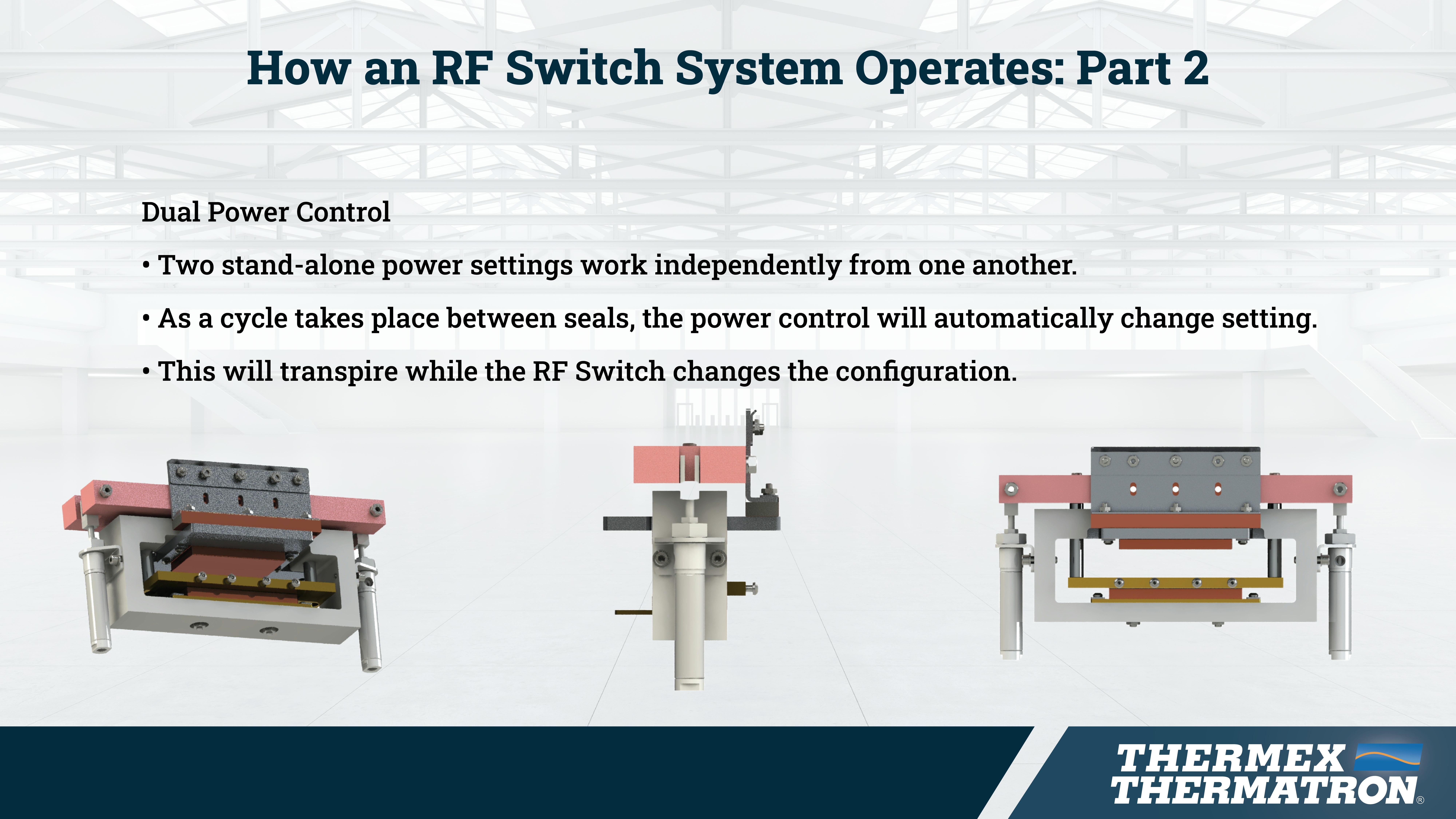

Dual Power Control

All adjustments to the power control are made through the HMI. With two power settings, in this system, each setting stands alone — completely independent from the other. Amid the portion of the cycle taking place between seals, the power control will automatically change setting while the RF Switch changes the configuration.

Generate Robust Seals with a Versatile, High-Powered RF Switching Network

Part of what makes the RF Switching Network so effective is its ability to allow the generator to move through two cycles at once during one press closure; all while maximizing different variable power levels along with distinctive variable sealing times.

Next, an integrated switch, incorporated at the press, is designed to switch the polarity of the sealing electrodes at the already preset power and time settings.

Using this innovative technique achieves well-balanced seals when tubing is placed between two sheets of vinyl. In the medical field, especially when facing a COVID era where expediting precise, high volume medical manufacturing solutions is more pressing than ever before, an intelligent RF Switching Network allows for bag outlines, tube insertions, and tear seals; all secured in the same, singular press closure.

Thermex – Thermatron RF Switches are designed with low electrical resistance, low inductance, and low friction for high efficiency and a long and productive life.

Utilizing RF Technology to Ensure Lifesaving Products and Treatment Are Available

By harnessing the power of RF welding, you can bolster key manufacturing processes, making in-demand products, well-engineered instruments, and fundamental equipment accessible. Along with IV bags, RF welding helps medical manufacturers deliver breathing bags to patients without sufficient oxygen. When a Thermex-Thermatron RF System has a high-functioning RF Switching Network receiving significant usage, manufacturers are able to accelerate production for all manner of needed products.

Drawing on the innovation of RF technology, hospitals can provide patients with compression leg sleeves, leading to better blood flow, less pain and swelling, along with yielding preventive benefits: the pressure on the blood relieves the risks of blood pooling that could cause dangerous clots. Because of an RF-sealed tourniquet, a patient whose life may have been otherwise threatened from massive blood loss is able to withstand hemorrhaging trauma; protected with a product made using revolutionary technology.

RF Systems can likewise help manufacture body bags. When a heat wave hit Washington last summer, body bags were packed with ice and doctors were able to save elderly patients from heat stroke — immediately bringing down their core body temperatures to lifesaving levels.

We Can Build Premier Presses and Sealers for You — Enhanced with RF Switches

Since 1939, Thermex-Thermatron has pioneered integral advances in radio frequency and microwave heating technology. Mining decades of research and real-world experience to develop front-line RF Systems, Thermex-Thermatron has engineered resources for manufacturers to optimize working conditions, assisting our customers in driving value-added, uniform results forward. Revamp productivity and throughput when you leverage machines with built-in power capabilities, custom-made for any manner of industrial processes needed.

We can create the RF Presses and RF Sealers you need, made more powerful with our newly re-designed RF Switching Network.

For more information, please visit our new website - thermex-thermatron.com.

For Thermex and Thermatron inquiries, contact our Director of Sales, Dean Mancuso (Sales@thermex-thermatron.com; 502/916-8972 or 502/243-5636.

For FIAB and Oteman inquiries, contact our Director of Business Development, Traci Evling (traci@thermex-thermatron.com; 502/916-8981 or 904/662-2169).