Tempering Frozen Food With Microwave Heat

Thermex-Thermatron Systems

For many production processes, incoming raw material is frozen in thin blocks and stored at

-10° to +15℉ until they are ready to use. In order to use these materials, they must be first tempered and secondly diced, sliced, or separated into smaller pieces. Paying attention to the tempering step is important because it helps prevent damage to the product. This delicate step is best done with microwave technology. Read on to learn about tempering frozen food with microwave heat.

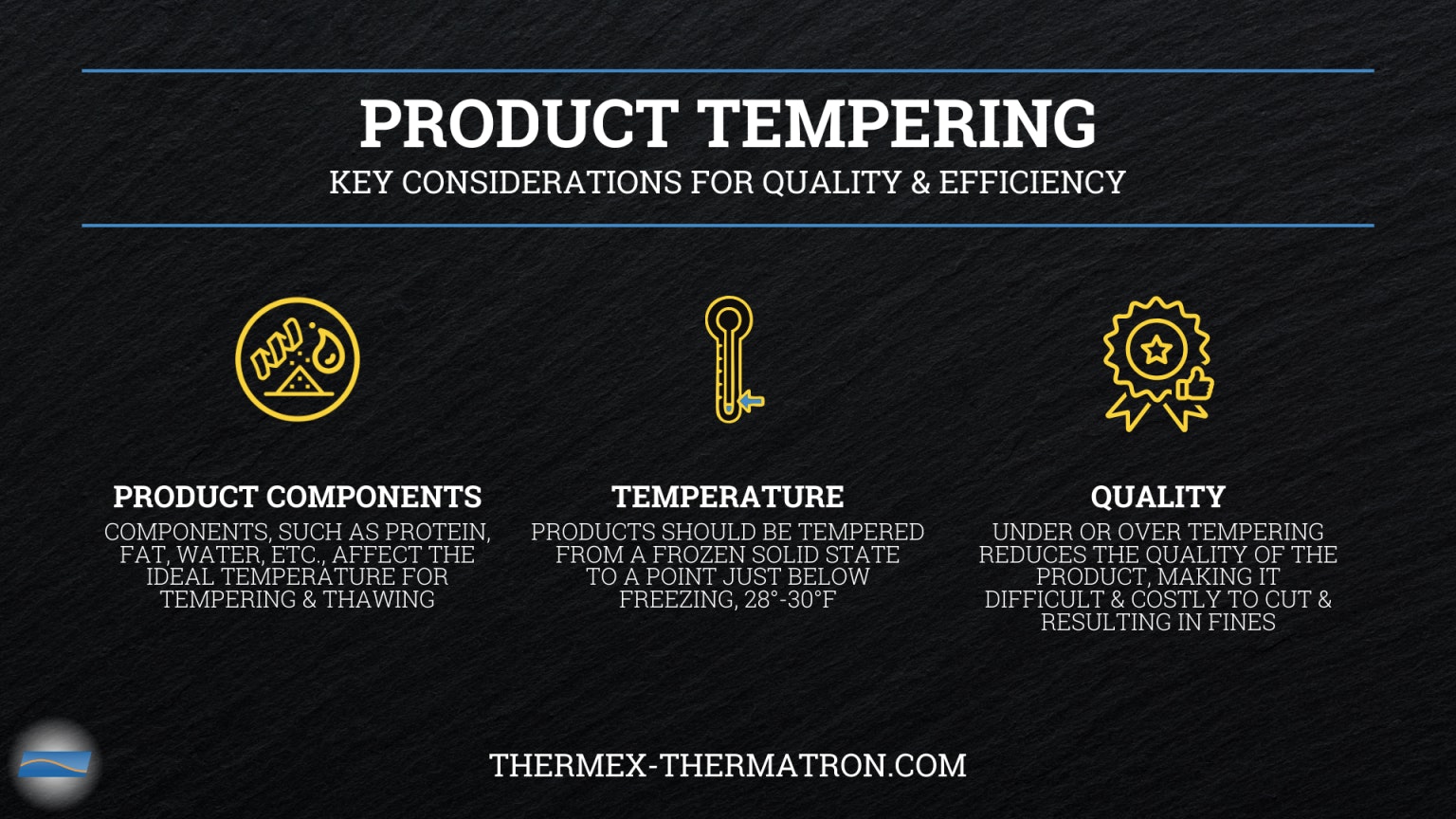

Understanding Product Tempering

Tempering should be done without overheating any part of the product. The ideal temperature will depend on the material’s components — such as salt, water, protein, fat, etc. — and the type of cutting, slicing, chopping, etc. required. In general, products should be tempered from the solid frozen state to a point just below freezing, 28° to 30℉.

Under-tempering can cause cutting blades to break, resulting in yield loss from shattered product, excessive fines, and inconsistent slices or pieces. The product may also become mushy, making its weight difficult to control, forming incomplete and poor product binding. Conversely, over-tempering lowers yield because of incomplete shearing of connective tissue. Like under-tempering, it makes weight control difficult, producing raggedness, stickiness, and wasted refrigeration resources.

Consequences of Conventional Heating

Conventional heating requires that the outside surfaces be exposed to higher temperatures for a longer period of time in order to conduct sufficient heat into the center of the product block. It is generally done using externally applied heat using hot air or water or, sometimes, simple floor tempering alone. After up to 48 to 72 hours, the result is temperature gradients that have parts that are over-tempered and under-tempered, all in the same block. The advantage of this method is that it does not require investing in any equipment. However, it demands significant floor space, labor and time, sanitizing, and double-handling, as well as large in-process inventory requirements.

The long processing cycle required brings other production challenges. It makes it difficult to plan ahead on orders or match material quality to orders placed. Foods all thaw more slowly as time progresses. This is because the conductivity of the product decreases by about two-thirds when thawed, causing heat to travel more slowly into the center of the block. This is problematic not only because of the time it takes but also because it creates an ideal environment for bacterial growth in the exterior of the product and surrounding drip mess.

These complications may be mitigated by using an engineered tempering room. Such rooms feature controlled in-flow that can hold products at temperatures to within 1℉ until equilibration is complete. This approach can still result in an over-thawed product exterior and under-tempered interior with significant temperature gradients.

With or without the use of an engineered tempering room, conventional heating often produces excessive drip loss of around 5%. In meat tempering, this loss contains 10% protein: 0.3 lbs of product loss from each 60lb block or 0.5lbs from each 100lb block. Additional disadvantages are loss of flavor and color.

The Advantage of Tempering Frozen Food with Microwave Heat

1. Microwave heating works differently to save production time and produce a higher quality tempering result. Using electromagnetic energy converted to heat, Thermex-Thermatron Microwave Systems heat simultaneously throughout each block. The heat is applied on a moving belt to food that is still in cartons and generally takes less than five minutes. In a dramatically shorter time than conventional heating, the result is more production time budgeted elsewhere and a high-quality, uniform tempering of the product.

2. Although use of microwave equipment incurs an upfront cost, the efficiency and quality it brings to production equals an overall lower cost over time. Microwave tempering reduces space requirements by up to 90% and saves up to 98% of production time. In terms of space, it reduces the amount of storage needed and eliminates the need for tempering rooms and racks. The drastically decreased production time also lowers and simplifies in-process inventory, cutting back on double-handling and advanced planning for orders. Each product can be matched by quality exactly as ordered without any danger of being disrupted by changing production plans.

3. A uniform, high-quality tempering optimizes products for additional processes. A better-tempered product is ideal for cutting, slicing, etc. as it both protects the cutting equipment and preserves the quality of the product. Material that is not over-tempered is also easier and faster to refreeze if needed. In cases of downstream equipment, there is little spoilage or contamination risk in production.

4. Thermex-Thermatron Microwave Systems allow cutting-edge precision and uniformity. By varying belt speed, BTU input to each block can be precisely controlled throughout the block. This allows the microwave to handle products with widely varying temperatures without losing equilibration. Variation of temperature throughout each block is typically less than ±0.5℉, eliminating the need for equilibration time after the product leaves the microwave unit.

5. The expediency increases yield while reducing labor. Tempering may take less than five minutes for products ranging from 0° to 26℉, producing a yield up to 7,500lbs per hour. This greatly improves sanitation and reduces sanitizing labor. Because microwave units can also temper boxed* or unboxed products, stripping cartons after tempering requires less work while one worker loads and unloads.

(* Containers that can remain on the food without disturbing the microwave tempering: polyurethane, polyester, polypropylene, corrugated cardboard, and plain cardboard.)

Sophisticated microwave technology is the natural choice for your production needs. Not only does it greatly reduce production costs, but it also dramatically improves product quality and yield. All of its benefits ultimately position food manufacturers for success that competitors using conventional heating simply cannot compete with. However, implementing a shift to this method is best done with the guidance and support of microwave system professionals.

At Thermex-Thermatron, our experienced engineers, and technicians are ready to help you and your team. We work to understand your specific production needs in order to recommend the best system that will be the smartest investment. Our technicians also stand by your new system by offering training and service to your operators, equipping them to use and maintain it with confidence and accuracy.

For Thermex and Thermatron inquiries, contact our Director of Sales, Dean Mancuso (Sales@thermex-thermatron.com; 502/916-8972 or 502/243-5636).

For FIAB and Oteman inquiries, contact our Director of Business Development, Traci Evling (Traci@thermex-thermatron.com; 502/916-8981 or 904/662-2169).