Industrial Microwave and RF Heating Is Green Technology

Thermex-Thermatron Systems

A leading pioneer in shaping essential microwave (MW) and radio frequency (RF) heating technologies, Thermex-Thermatron Systems (“Thermex”) has empowered top industries to apply dielectric heat quickly and consistently; paving the way for skillful and lucrative mass production. Engineered with the benefits of advanced and innovative capabilities, these highly designed systems are made to assist factories in safely accelerating throughput — transforming the craftsmanship of each product.

Industrial microwave and RF heating technologies offer a multitude of advantages in the changing world of process heating; allowing manufacturers to unlock sharper quality, productivity, and profitability; with unmatched versatility. Thermex-Thermatron has optimized decades of insights into the intelligent design of agile MW and RF equipment. Created to deliver dynamic heating for an array of process needs, each Thermex system has been carefully engineered — primed to serve industrial applications all around the world.

Furthering advancements in clean energy transfer, Thermex has built process-simplifying systems. Set to boost colossal energy savings, minimize spatial footprints, and offer strategic control over heat loss, manufacturers can ensure every ounce of thermal energy is utilized: achieving uniform results that are both energy-efficient as well as cost-effective.

Changing the Way Heat Is Applied —

Protecting Industrial Processes from Massive Heat Loss

Modern production facilities have come to learn: microwave and radio frequency processes can yield more value-added, energy-saving solutions than other methods. As a result, MW and RF heating technologies have been revolutionary for industrial settings. Harnessing an extensive background in cutting-edge engineering, Thermex-Thermatron has assisted customers with the development of high-powered equipment; facilitating systematized industrial process heating across multiple industries and throughout various applications.

There is more to gauging performance than assessing a heat source’s capacity to turn input into heat. While resistance (electric and gas) efficiently convert input into heat, consider that it is in the application of that very heat through conduction, convection, or radiation that significant losses can otherwise occur. Conversely, when applying MW and RF technology, unlike with other methods, the heat required for the process is developed within the processed materials themselves.

Because MW and RF technologies are strategic in their generation of heat, with heat focused inside the processed material, this uses less power to heat the same mass of material. Moreover, any losses incurred in transferring the energy into the product are minimal. As such, these green technologies can be up to 50% more efficient than other methods.

Thermex has dedicated over 80 years to researching every facet of industrial microwave to RF heating technologies; leveraging this in the design and development of powerful machinery manufacturers can trust. Proven to elevate industrial process heating, MW and RF heating are well-established clean heat technologies. In applications where demanding requirements such as close temperature tolerances or processing in specialized environments are paramount, the ability to immediately control power in a MW or RF system is a key asset.

Providing Manufacturers the Versatility to Satisfy Strict Industry-Wide Requirements

Food processing arenas to pharmaceuticals as well as medical industries need the ability to regulate low temperatures in large-scale industrial settings and heating operations. As a general rule, close temperature tolerances are application dependent. After all, an abundance of applications necessitate inert, oxidizing, or reducing atmospheres. Certain processes require moisture leveling, equalization, or finely tuned activation of chemical reactions.

As far as applications that call for stringent specifications, the implementation of these technologies for close temperature tolerances can be as green as the power supplied; whether wind, solar, or hydroelectric, which is carbon neutral. Using trustworthy technologies to meet these specific requirements allows manufacturers to not only produce green outcomes, but to secure repeatable, diligent accuracy; no matter the exacting stipulations or rigid conditions at play.

Before manufacturers could draw on MW and RF heating, traditional process heating relied on natural gas or steam, derived from oil or coal-fired boilers. In the past, these would have served as the most economical methods; where conventional electric heat struck a marked disadvantage: this source of heat and its resultant processes are substantially more expensive.

Notably, conventional processes use conduction to heat an item outside-inward. The energy of conventional electric heat travels differently than with MW and RF technologies, where polarized molecules boost temperature to heat the materials. Therefore, it is instrumental that MW and RF heating technologies offer such a unique combination of properties — qualities not available in the more traditional heating processes.

Understanding the Step-by-Step Process of Electromagnetic Heating

In almost every application, MW or RF heating cuts processing time, reduces or eliminates waste, and increases quality and uniformity. First, microwave and radio frequency energy cause molecular rotation to occur in materials containing polar molecules. Then, those polar molecules will align themselves in an electromagnetic field. If that field is oscillating, the molecules rotate continuously; colliding with other molecules, distributing the energy to adjacent molecules in the material. Agitating the molecules in this way thereby increases the temperature of the material.

The Impact of New Environmental Regulations:

How Green Technology Can Better Support Profits

Meticulous accuracy and control are not only accessible with state-of-the-art technical equipment; they are essential to fulfilling rising demands in a world of escalating, exorbitant costs. Investing in Thermex’s industrial microwave and RF heating systems eases and streamlines in-process inventory; where production is able to meet precise needs, just as ordered; sparing operations from the disruptive risk of shifting external variables.

Present-day, more and more production facilities are turning to industrial microwave and RF heating equipment. Because these technologies allow for heat to be generated within the processed materials, MW and RF systems are poised to support the most efficient transfer of energy. Not only is less thermal insulation required, but less waste heat is generated.

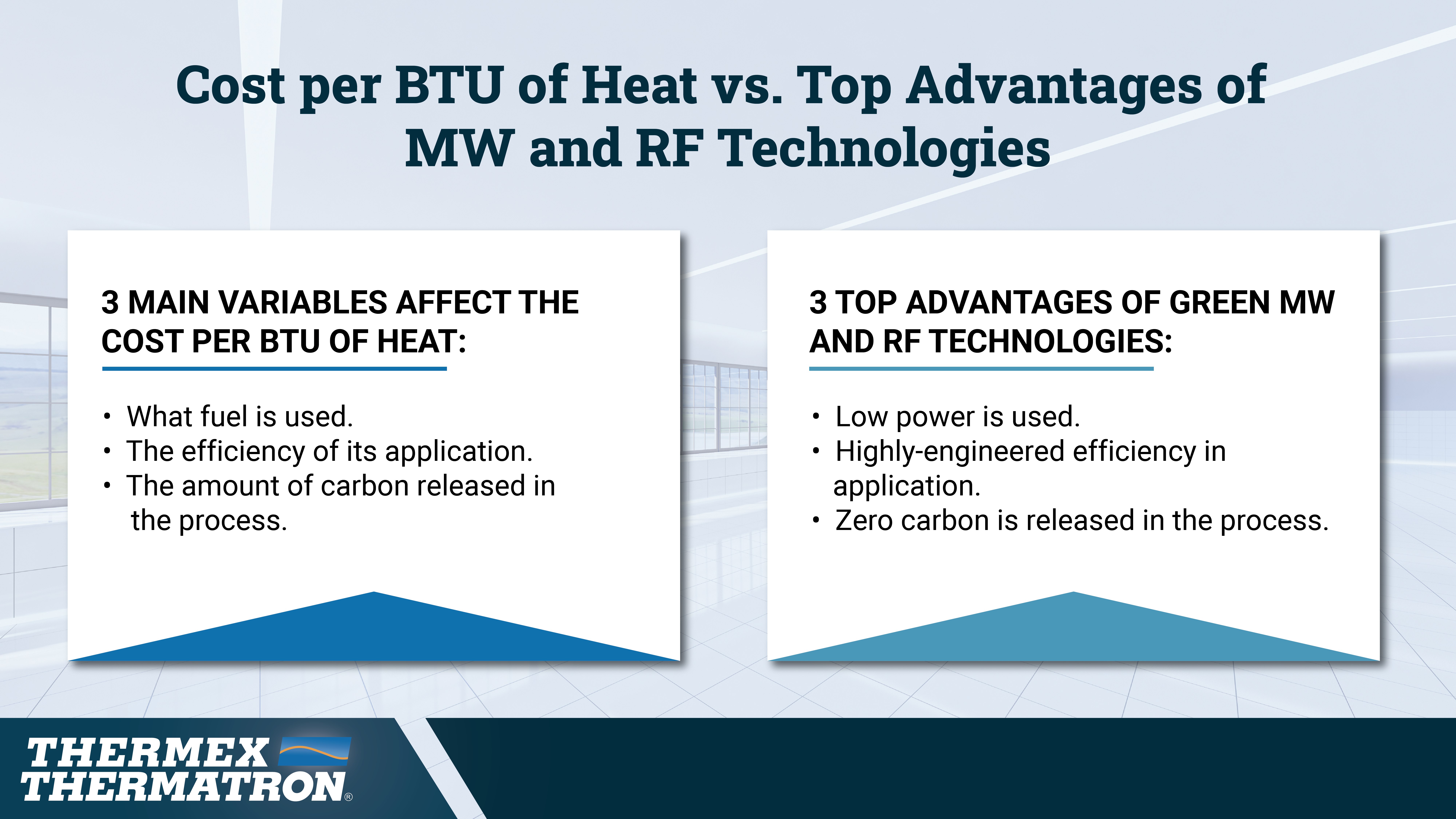

Additionally, rising environmental regulations are forcing a shift in this paradigm. Consider that the cost per BTU of heat will continue to grow steeper as fuel prices skyrocket. However, what specific fuel is used, how efficiently it is applied, as well as the amount of carbon released in the process will determine the ultimate cost.

When factoring this kind of expense, it is a budget-savvy reward for a manufacturer to use either MW or RF technology; as neither of these resources releases any carbon whatsoever. Rather than trying to negotiate ways to level the cost with fuel choices, or navigate efficiency subject to human error, when using Thermex’s systems, facilities can reach supremely high material temperatures — with easy-to-use MW or RF generators. This means commensurably low power and zero carbon to hike up expenses. Manufacturers can achieve replicable, labor-saving, skillful craftsmanship in bulk.

The Value of Electromagnetic Energy:

Speeding Up Processes Pares Down Energy Consumption

Microwave and RF energy are capable of penetrating materials of poor thermal conductivity. Instead of prolonged heating in a conventional system waiting for external heat to “soak” into the product, heating begins immediately through the entire product as soon as power is applied. This dramatically reduces energy usage by shortening process times and eliminating the need to keep the energy input to the system at process levels when not needed. Virtually no warm-up is required.

In many applications, microwave and RF energy can be targeted at a specific component or material within a product — producing heat only where it is needed through a process known as selective heating. Consider that industrial microwave and radio frequency equipment emit no greenhouse gasses. This thereby eliminates the need for air quality monitoring, as well as any fines or penalties from outdated, malfunctioning combustion systems. While not all industrial applications are suitable for microwave or radio frequency heating, for many, these powerful technologies offer more heat on target; all at rapid-fire speed; using less energy than any other method.

Reliable, top-of-the-line technology not only supports factories in adapting to a changing modern landscape; it offers production floors the benefit of trusting in recognized industry leaders. Developing robust microwave and radio frequency equipment, Thermex has built breakthrough resources for manufacturers racing to satisfy evolving pressures and demands. Our engineers understand exactly what tools assembly lines count on — creating premier systems ready to run safely and effectively for any end user.

We have the breadth of knowledge and high-level capabilities to customize solutions for any need pivotal to your production goals. This allows manufacturers the opportunity to invest in a partnership; where with the support of Thermex’s engineers and our in-house laboratory, ThermaLab — a space where you can ensure you match the best possible technology for its ideal application — you can yield long-lasting products, time and time again.

For more information, visit our website at thermex-thermatron.com.

For Thermex and Thermatron inquiries, contact our Director of Sales, Dean Mancuso (Sales@thermex-thermatron.com; 502/916-8972 or 502/243-5636).

For FIAB and Oteman inquiries, contact our Director of Business Development, Traci Evling (Traci@thermex-thermatron.com; 502/916-8981 or 904/662-2169).